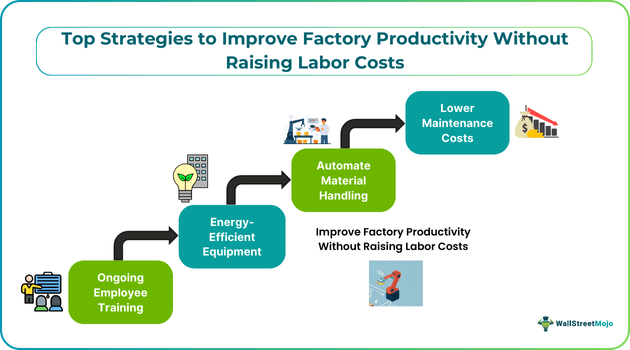

Top Strategies to Improve Factory Productivity Without Raising Labor Costs

Table of Contents

Introduction

Rising costs significantly affect manufacturing companies. It not only erodes their profit margins but also reduces its competitiveness in the market. Increased costs force companies to raise the cost of their products, thereby losing customer loyalty, who shift to cheaper brands, even if means a slight reduction in quality.

Companies eventually lose market share, and their business may even fail. Thus, it is important for manufacturing companies to improve productivity without raising the cost of labor. They must adopt strategies that can eliminate the impact of rising costs.

This not only helps the preserve their profit margin but also ensure that they are sustainable in the long run. In this article, let us look at some of the key strategies required by manufacturing businesses to improve productivity without a hit to their labor costs.

Invest in Smarter Cutting Tools

Every product on a factory line begins with cutting. Sheets of metal, slabs of wood, or molded plastics all need shaping before they move further down the line. The problem? Outdated tools slow the process, waste valuable material, and lead to unnecessary rework.

This is where modern machines change the game. A plasma cutter is one example. If you’ve ever wondered How does a plasma cutter work?, the answer lies in speed and accuracy. It uses ionized gas to slice through metal with a clean edge that older methods simply can’t match. The result is less scrap, faster turnaround, and far fewer errors.

Pair that with CNC integration, and you unlock even more efficiency. Instead of relying on manual adjustments, the cutter follows programmed instructions with precision. One operator can manage more production, while the machine keeps quality consistent from the first cut to the last.

Key benefits of advanced cutting tools:

- Faster production with precise results.

- Lower material waste and scrap rates.

- Safer operation with fewer manual errors.

That’s the real benefit of smarter cutting tools: they give factories more output without demanding more hands on the floor.

Automate Material Handling

Automating material handling involves using computer-controlled systems like Automated Guided Vehicles (AGVs) and Automated Storage and Retrieval Systems (ASRS). Also, conveyors that can move, store, and manage materials efficiently are also important in industries such as manufacturing and warehousing.

Automating material handling can reduce labor costs, minimize errors and optimize inventory management. When we integrate technologies like barcoding and RFID with these systems, it can be one of the best factory optimization techniques.

The advantage of Automated Guided Vehicles (AGVs) is that they increase efficiency and safety by automating material transport, reducing labor costs, and minimizing errors in factory operations.

Embrace Preventive Maintenance

Preventive maintenance is the regular, planned servicing of equipment to prevent unexpected breakdowns and extend its lifespan.

To implement preventive maintenance measures, consider the following steps:

- Regular inspections and servicing of machinery help identify potential issues before they cause major disruptions in your manufacturing process.

- Using sensors to gather real-time data that shows equipment performances helps detect anomalies and make immediate adjustments.

- Maintenance activities can be done during non-peak hours to avoid disruption in production.

- Implementing such preventive measures go a long way in improving your business profitability.

Use Energy-Efficient Equipment

Energy costs are Achilles heel for any business which is perfect in other ways. To lower your bills and boost sustainability, you can implement some smart upgrades.

Find out where the energy is being utilized. Energy audits will help you spot inefficiencies in any stage of your manufacturing processes. Before making changes, figure out where your energy is going. Once you know what’s draining power, you can take steps to cut down the energy waste.

Outdated machines can cost a lot and investing in energy-efficient equipment can help use less power. All the latest models come with smart features that help you monitor usage.

Energy-efficient upgrades can significantly cut factory energy consumption, making them a smart long-term investment that boosts profitability without raising labor expenses

Rethink Factory Layouts

A factory layout that is optimal should consider the efficient flow of materials and people. An ideal layout is one that allows easy movement of materials and equipment. There should be no obstruction and potential hazards where workers are aplenty, should be avoided.

Appropriate warning signs that provide vital information should be installed to alert workers in case of any hazards.

Always ensure that the factory premises are clean and proper waste removal protocols are in place to improve safety measures at any factory.

Provide Ongoing Training

Your factory workforce can be completely productive only when they are trained. A skilled workforce is one which makes fewer mistakes and can be flexibly allocated where required. Training employees with the latest equipment and technology used in your factory can create a positive workplace environment.

As a business owner, remain committed to regularly training your employees. This will help reduce the cost and production impact of churn. A Connected Worker Platform supports this by giving employees real-time access to procedures, updates, and shift context, so training actually carries over from one shift to the next instead of getting lost in handovers.

Conclusion

Using advanced tools, implementing energy-efficient processes and automated material handling helps drive efficiency within heavy industries. Implementing cost saving strategies described above helps improve precision, extend tool life and boost productivity without extra labor. Integrating our workflow processes with modern technologies improve factory productivity and saves cost.