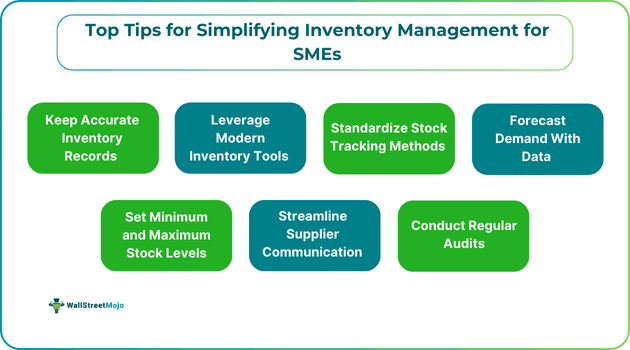

Top Tips for Simplifying Inventory Management for SMEs

Table of Contents

Introduction

Efficient inventory management for SMEs is crucial to ensure profitability. When small businesses fail to manage their raw materials and products properly, they cannot maintain an optimal financial position. For example, if the inventory level is too low, they cannot fulfil the demand of customers who end up making purchases from competitors. On the other hand, having excess stock can result in cash flow issues. If businesses have a reliable and effective system in place, they can simplify inventory management. This, in turn, can result in minimized costs, streamlined operations, and better business efficiency.

While working with a trustworthy SAP Business One partner is a popular way to manage inventory effectively, there are other measures organizations can take to achieve the objective. In this article, we’ll provide you with the tips and techniques you may consider using to ensure efficient inventory management.

Keep Accurate Inventory Records

For ensuring small business stock control, maintaining accurate inventory records is essential. Such records typically include lot numbers, supplier data, country of origin, stock-keeping unit or SKU, and barcode data, along with other information, if applicable. Moreover, small business owners should consider monitoring the costs related to each item over time so that they are aware of the elements that impact pricing, for example, seasonality and scarcity.

When a business maintains correct stock-related data, it can steer clear of inventory shortage and dead stock. In other words, by following this practice, they can ensure informed decisions related to the purchase and sale of goods or materials.

Businesses can consider using effective inventory management software as well as tools like a barcode scanning system to monitor stock and ensure accurate record-keeping. Let us learn more about such tools that simplify warehouse management for SMEs in the next section.

Leverage Modern Inventory Tools

Organizations should consider investing in the latest tools that allow them to track stock levels automatically. Such tools refer to inventory management software, barcode scanners, etc., as mentioned earlier. Inventory management software can help save time significantly. Moreover, it can reduce the chances of errors, which are associated with manual stock monitoring. Such tools can eliminate the guesswork and offer real-time updates that can ensure business owners can conduct operations smoothly.

Note that one can also use the historical inventory data accumulated using such software to predict future trends and estimate demand. Business owners may integrate such solutions with other business systems, for example, e-commerce platforms and a point-of-sale or POS system, to improve organizational efficiency.

Besides having an inventory management application, having barcode scanners is important as these tools allow businesses to scan items and update stock information in real time. They can integrate with the software easily, enhance accuracy, reduce errors, and improve stock visibility without the need for any significant investment.

Standardize Stock Tracking Methods

Another important inventory management tip that most experts give is to introduce standardized procedures concerning stock tracking. Indeed, standardized methods can lead to the creation of accurate and consistent inventory data within the organization. This, in turn, can result in better decision-making. Moreover, standardization can decrease operational expenses and enhance efficiency. Standardized processes can make sure all team members work in a specific way with the exact data, which is vital for ensuring effective small business stock control.

Having said that, introducing standardized procedures will require companies to provide proper training to the relevant employees so that they can understand the best practices and ensure efficiency. Note that well-trained staff is imperative for effective inventory management for SMEs and avoiding costly mistakes.

Forecast Demand With Data

Predicting customer demand is a challenge for businesses. If the prediction is incorrect, it can lead to overstocking or stockouts, and neither is favorable for a business’s profitability. That said, with solutions like SAP Business One, estimating demand on the basis of historical stock data has become straightforward. Indeed, businesses can use the past inventory data recorded on the software to predict future trends. This can help them reorder products at the right time so that they can fulfill customer demand and avoid cash flow issues.

Set Minimum and Maximum Stock Levels

Another common practice carried out by organizations to carry out efficient inventory management for SMEs involves setting minimum and maximum inventory levels for every product. When the stock level reaches the minimum threshold, the company reorders stock to ensure that the maximum stocking limit is reached again. The maximum limit prevents a company from overstocking and overspending.

This approach minimizes the possibility of overspending or underspending and can play a key role in optimizing inventory management. Essentially, this method involves maintaining the on-hand stock within a specific range.

Streamline Supplier Communication

Another key practice necessary to simplify inventory management involves streamlining the communication with suppliers or vendors. It is important to get clarity from suppliers regarding delivery time and the quality of products. Knowing such information beforehand is vital for avoiding delays and steering clear of customer dissatisfaction.

To establish effective communication that can ensure efficient inventory management for SMEs, business owners can consider using a common platform to exchange documents and any information digitally. It can help in avoiding delays and the costs linked with processes that rely on manual and paper-based approaches. Experts recommend using cloud-based solutions that integrate with suppliers’ systems for this purpose.

Conduct Regular Audits

The last important tip for simplifying inventory management for SMEs is to carry out stock audits at regular intervals, for example, monthly, quarterly, etc. Such period audits can help in the identification of errors or discrepancies.

Upon identification, the relevant people within the company can take the necessary measures to address the issues and make sure that the stock available physically with them matches the records. Although such audits can be time-consuming and disrupt the day-to-day operations, they are vital are avoiding the risks of dead stock, stockouts, and overstocking. Moreover, such audits are essential for ensuring that the stakeholders keep their faith in the company.

Once business owners or managers are aware of the above tips to ensure efficient inventory management for SMEs, they can use them to manage stock levels better and improve the company’s overall performance.