Table of Contents

What Are Micro-Fulfillment Centers (MFC)?

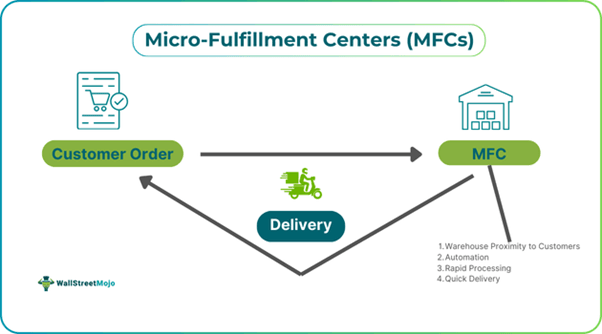

Micro-fulfillment centers (MFCs) refer to small-sized warehouses strategically located to streamline the logistics process of online retail orders, particularly in sectors like e-grocery. They help e-commerce retailers keep their inventory closer to the end user to cut transit times and costs, increasing operational efficiency.

MFCs tend to be highly automated to improve operational efficiency. They typically store fast-moving, high-demand goods to facilitate faster fulfillment. MFCs can handle up to 10,000 SKUs of goods through their urban network of strategically located centers. This helps meet consumers' expectations for faster delivery while remaining cost-effective.

Key Takeaways

- Micro fulfillment centers (MFCs) are strategically positioned warehouses designed to optimize the logistics of online retail orders.

- Benefits of MFCs include enhanced customer service, cost-effective expansion for smaller businesses, quick deliveries, faster fulfillment, increased product sales, streamlined logistics, and reduced fuel and labor costs.

- Limitations of MFCs include complexity in inventory management, the need for constant replenishment, high transport costs, unpredictable demand, stock outages, unsuitability for all SKU types, expensive automation, and limited inventory assortment.

- MFCs are small in size to enable fast order processing and delivery, whereas dark stores are traditional retail stores converted into online fulfillment centers.

How Do Micro Fulfillment Centers Work?

Micro-fulfillment centers (MFCs) function as small-scale warehouses and distribution centers strategically located near customers to speed up order fulfillment and distribution. Local retail stores, larger distribution centers, and online retailers attach these centers to achieve last-mile delivery and reduce operational costs.

MFCs generally deploy sophisticated automated systems to process and ship online orders quickly and efficiently with minimal staff. Automation handles packing, stock management, and order distribution, reducing the need for human labor and increasing operational efficiency. As a result, some MFCs can process up to 4,000 orders weekly despite their compact size. This has multiple implications for retailers, such as reducing delivery times for perishable and urgent goods like medicines.

MFCs also lead to cost savings by reducing transportation expenses, as they don't rely on long-distance shipping, and by lowering real estate costs through the use of smaller, compact warehouses. Additionally, they enhance customer satisfaction and loyalty due to faster delivery and a wide product selection.

MFCs also face certain challenges, such as the need for proper site selection, efficient inventory management, and integration with Warehouse Management Systems (WMS) or Enterprise Resource Planning (ERP) systems for smooth operations. Despite these challenges, MFCs have gained popularity, as seen with Walgreens and Walmart launching micro-fulfillment centers in India.

Examples

Let us take the help of a few examples to understand the topic.

Example #1

Let us assume a city where the e-commerce corporation Techmart operates, facing challenges with last-mile delivery and high demand for quick order processing. To solve this problem, Techmart assesses the situation and decides to implement micro-fulfillment centers (MFCs). The company scouts for strategically located sites in and around densely populated areas of the city. After identifying suitable locations, it implements an automated MFC system with minimal human intervention to streamline online retailing and delivery.

As a result, Techmart can meet customers' demands for high-volume and faster delivery requests in a fraction of the time. This improvement enhances customer loyalty and reduces operational costs. Consequently, the company experiences unprecedented business growth and becomes profitable.

Example #2

Amazon explored automated micro-fulfillment centers (MFCs) to enhance its logistics and order fulfillment, aiming to place small warehouses in densely populated urban areas for faster deliveries. The company significantly ramped up its investment in MFC technology, establishing several automated centers that enable rapid order processing and delivery within hours. This expansion addresses the growing consumer demand for swift online shopping experiences and allows Amazon to compete with other retailers, leveraging similar strategies. Micro-fulfillment enables brands to ship inventory directly to these centers, facilitating efficient order fulfillment.

Benefits

Retailers who adopt this approach derive the following benefits:

- Quicker deliveries and pickups, often within an hour or two after customers place an order.

- Accelerated order fulfillment through automation, enabling doorstep delivery as soon as orders are received.

- Logistics processes are greatly streamlined.

- Reduced unnecessary expenses, such as fuel costs associated with delivery and pickup.

- Lower labor costs, as most automated processes, require minimal human intervention.

- Enhanced customer service and experience through faster deliveries and more efficient handling of returns or refunds.

- A cost-effective way for smaller businesses to expand with minimal investment.

- By offering affordable and faster shopping, product sales see significant increases.

Limitations

Retailers must consider the following limitations of MFCs before adopting them:

- Expensive automation technology and high-quality machinery are required, which can be challenging for some retailers.

- While space is optimized, the assortment of available inventory is limited.

- Inventory management becomes more complex.

- Constant replenishment is required, as inventory can only be stored for 48 hours.

- High transportation costs for routine goods transfers between locations.

- Limited space makes it difficult to adjust to unpredictable demand for certain goods.

- Stockouts are more likely due to unpredictable demand, disrupting optimal stock levels.

- Changes in customer profiles or market conditions can negatively impact operations, as MFCs heavily depend on consumer locations.

- Not suitable for all SKU types, particularly larger items.

Micro Fulfillment Centers vs. Dark Store

MFCs and dark stores optimize the last mile and fast delivery of goods but differ in the following ways:

| MFCs | Dark store |

|---|---|

| Small in size for fast order processing and delivery. | Traditional retail stores converted into online fulfillment centers. |

| Optimized compact spaces for efficient storage in urban areas. | Occupies larger spaces, often from converted physical retail stores. |

| Strategically located in densely populated urban areas to enable faster order fulfillment. | Primarily located in urban areas to serve online customers. |

| Heavily robotized and automated for sorting, picking, and packing processes. | May involve both technology and physical labor for processing. |

| Facilitates adaptability and scalability in response to varying market conditions and demand. | Offers versatility to businesses for managing different types of orders and products. |

| Automation and efficient space utilization help lower operating costs. | Operating costs vary based on the level of automation and warehouse size. |

| Enhances customer satisfaction by improving the online shopping experience. | Enhances delivery speed for customers. |

| Enables businesses to fulfill orders quickly and efficiently. | Provides contact-free shopping. |