Table of Contents

What Is Risk Pooling In Supply Chain?

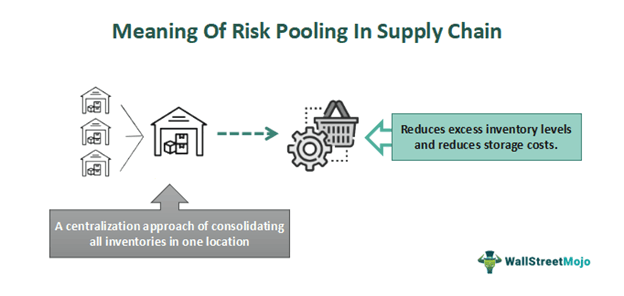

Risk pooling in supply chain management refers to the centralization approach of bringing inventory to a single place (or warehouse). It resides in warehouses having many product lines. Thus, it aims to manage and optimize inventory levels to fulfill the existing demand rather than owning multiple warehouses.

Unlike decentralization, the concept of risk pooling concentrates on centralization. It aims to have a single place of inventory storage to avoid stockout. Firms can reduce the likelihood of excessive stock levels and avoid spoilage. Furthermore, risk pooling is particularly advantageous in scenarios with bloated inventory levels where demand is highly variable.

Key Takeaways

- Risk pooling in supply chain refers to the consolidating of the different warehouses into a single one to cater to the product demand. Companies with multiple product lines mainly use it.

- This approach focuses on centralization instead of decentralization. The focus of this model is to operate the supply chain from one location.

- The different types include inventory, centralized, and product pooling. The issues of bloated inventories and unwanted (or excess) stock levels may reduce considerably.

- This approach may lead to increased transportation costs and longer delivery periods.

Risk Pooling In Supply Chain Explained

Risk pooling in supply chain is a risk management tool used to aggregate all inventories in one place to fulfill business demand. This strategy involves accumulating demand from different regions and multiple product lines. A company owning only one warehouse instead of several mitigates the risk of unwanted or excess inventory. Also, risk pooling helps in balancing demand fluctuations in the product lines.

The primary aim of using risk pooling is to reduce the risk that occurs from the inventory levels. In business operations, companies may engage in the distribution of multiple product lines. If it happens, the chances of receiving fluctuating or uneven demand are high. For instance, Products A, B, and C might have more demand than Products D and E. And this demand can also vary with region. Thus, firms tend to own multiple warehouses to fulfill demand and facilitate better customer service. However, it does increase the cost of storage and inventory. As a result, risk pooling methods reduce this risk and pool in a single location.

There are different types of risk pooling in supply chain management, including centralized, virtual, inventory, and product pooling. Let us understand them in detail:

- Centralized risk pooling: Here, the distribution and logistics of business get centralized in one place. As a result, the need for multiple warehouses is reduced.

- Inventory pooling: In this type, the stock or inventory is kept in one single place, aiming to fulfill the local demand of the business.

- Virtual pooling: Among the different types of risk pooling in supply chain, virtual pooling focuses on the virtual centralization of inventory or warehouses via electronic format.

- Product pooling: It refers to the risk pooling strategy where multiple product lines or SKUs (Stock Keeping Units) are clubbed in one place.

Examples

Let us look at the examples to comprehend the concept better:

Example #1

Suppose Samuel is a businessman dealing in stationery products. In the past ten years, he has established a business that has around ten warehouses near the production plant. Thus, whenever orders strike the cart, the logistics team tries to deliver them in less time. However, in the last few weeks, Samuel noticed an unusual change in the orders. After analysis, Samuel observed that demand for the products was higher in one city while remaining low in other regions.

However, the time taken to deliver them remained consistent. Consequently, Samuel contemplated changing the distribution approach. After a brainstorming session, Samuel decided to close all the remaining warehouses and operate just one. All the inventory was now shifted back to the main warehouse, where the demand was high, and started distribution from that point. As a result, the delivery taken by the executive agent was reduced to half.

Example #2

Suppose a supplier, Jamie, follows a decentralization approach with three warehouses supplying in Markets A, B, and C. Each warehouse caters to each market individually. However, in this scenario, she cannot focus on any other market as they are confined to one at a time. In contrast, Joseph, another supplier, implements centralization in supply chain management, utilizing a single warehouse to serve multiple markets. This centralized approach eliminates the need to maintain multiple storage units, reducing associated costs.

Best Practices

Firms follow many practices as a part of supply chain management to mitigate the risk associated with this field. They help in identifying factors that support the need for risk pooling in the business. Let us understand them in brief:

- Identifying the trade-offs in business: The first step in applying this concept is to understand its trade-offs. It means that centralization often leads to a rise in transportation costs. Moreover, it takes longer delivery time as the distribution occurs from a single warehouse. Therefore, it is necessary to understand the need for risk pooling and trade-offs benefitting from risk pooling and still reduce the costs.

- Determining sources influencing the demand: Businesses can analyze their demand graph while implementing this model. It includes identifying the sources that cause uncertain or variable demand over a certain period. For example, the demand may be high in one region and extremely low in another region. Thus, resources can be diverted to the regions with the greatest need.. Moreover, even the supply chain can be influenced when sharing the risk and reward in pooling.

- Selecting the right type of risk pooling: After analyzing the uncertainty in demand, the next step involves selecting the right type of risk pooling to solve the issues. For instance, if the business has a 90% demand from the west side of the United States, having a single warehouse (or centralized risk pooling) is beneficial. However, the type may change in the business models concerned with the overseas market.

- Implementing the approach: Once selected, firms can implement the risk pooling method in their supply chain model. It will ensure that the approach caters to the needs of the business and reduces inventory costs. Also, it is advisable to monitor and update the process whenever required.

Advantages And Disadvantages

Following are the advantages and limitations of risk pooling majorly observed in supply chain management. Let us understand them in detail:

| Advantages | Disadvantages |

|---|---|

| Risk pooling helps identify sources that lead to variable demand. | It leads to increased transportation, distribution costs, and longer delivery times. |

| It reduces the risk of bloated inventories and unwanted storage costs with multiple inventories. | At times, it may be challenging to cater to high demand with only one warehouse. |

| There is efficient resource utilization as there is no excess inventory stocked up. | It can cause delayed lead time from the start until it reaches the end consumer. |

| It decreases the overhaul cost and increases the service level for the business. |