Table of Contents

Supplier Management Definition

Supplier management is the process of identifying, onboarding, transacting, and collaborating with suppliers who have an approach to business that is similar to the organization. The process is an attempt to extract the maximum value from suppliers for the money paid to them. Since suppliers are an integral part of business development, both parties need to communicate and collaborate effectively.

Establishing a solid supplier management relationship, clear communication and the ability to manage requirements is a non-negotiable for an organization to ensure that the following products are intact and that the quality and pricing are top-notch. Ultimately, the process looks to promote transparency at every level to ensure a seamless relationship and maximum value addition for both parties.

Key Takeaways

- Supplier management is the process of overseeing relationships with suppliers who supply goods or services to a business. The process includes deciding organizational objectives, selecting relevant suppliers, and tracking their performances.

- Once a supplier is onboarded, terms and negotiation processes commence. Once a mutual agreement is met, the management team tracks their performance.

- The ultimate goal of the process is to ensure that decided terms are consistently delivered and the maximum value is derived from the relationship.

- It is, however, crucial to ensure that the quality is consistent, pricing is competitive, and the delivery is on time every time.

Supplier Management Explained

Supplier management refers to the process that helps with managing suppliers and enhancing their positive impact on the organization. The supplier management system encourages both parties to collaborate and develop new processes that can benefit the overall business that comes out of this relationship.

The building block for a successful relationship with respect to this scenario is being transparent. Transparency allows both parties to look at the data objectively, which shall improve the relationship and, thereby, grow each other's business.

Primarily, any business wants to ensure its customers get the best quality products at the best possible prices, for which procurement plays a critical role. Establishing a cordial relationship with vendors or suppliers can ensure that products are procured at the best price after negotiating back and forth.

Once the management system is in place, it becomes easier for suppliers to understand the organization's business better. It helps the vendors understand the requirements of the business and supply goods as per their requirement history and alerts them if there are any expected supply chain-related delays.

On a global level, supplier relationship management (SRM) has grown beyond orthodox cost reduction strategies. Since they are more integrated and eliminate the strategic hide-and-seek between parties, it is more prominent and efficient to conduct business activities.

A good relationship between vendors and businesses is like an extension of the same organization. They work towards each other's growth and support each other's vision by providing good quality products in a timely manner and at stable prices.

Process

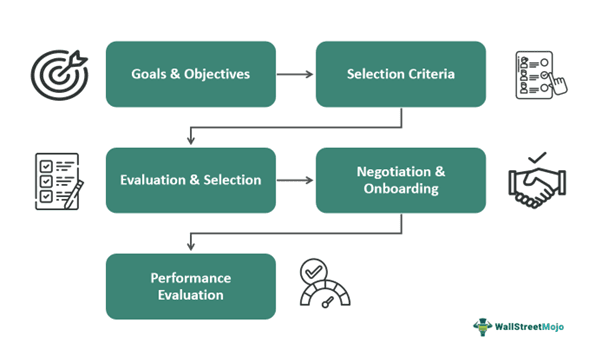

Supplier management software is the go-to option in the modern day. However, it is crucial to understand the intricacies of the process to be able to tell right from wrong in the practical world. The process is explained in detail through the points below.

- Business Goals And Objectives: Much before any business organization finds suppliers, they must first understand their own goals and objectives. It not only gives them clarity but also helps them find suppliers that align with the thought process. It also helps organizations gauge the performance of the vendor in comparison to the requirements that were communicated to them.

- Selection Criteria Identification: Once the goals and objectives of the organization are defined, they can then curate the requirements for their suppliers. The requirements differ from organization to organization. However, the standard criteria for vendors or suppliers are competitive pricing, quality, legal compliance, and legal reputation.

- Evaluation And Selection: Based on the criteria and requirements set by the organization, a prospective list of suppliers is evaluated based on all the factors such as pricing, quality, delivery time, and so on. The suppliers that best fit the organization's goals and objectives have been selected.

- Negotiation and Onboarding: Once the relevant suppliers are shortlisted, vendors are included in the process of carrying out the final negotiation before onboarding them as suppliers. All related parties are included in the process to ensure no ends are left loose. Once the negotiation is complete, the suppliers are onboarded.

- Performance Evaluation: The onboarding marks the beginning of the relationship between the organization and the supplier. After the supplier starts delivering the goods as per the discussed parameters, a team from the organization constantly monitors their performance to ensure all discussed factors are covered consistently.

Examples

Understanding a concept is always easier through practicality and real-life application. The examples below shall boost the understanding of the concept and its intricacies.

Example #1

MNO Nurseries supplies indoor and outdoor plants through their physical stores across 25 locations and through their website as well. To widen their range of services, they also took up landscaping projects.

To ensure all their clients got the best services at more competitive prices than the rest of the players in the market, they evaluated more than 50 potential suppliers for the 25 locations they are operating in. They went through pricing, creativity, and knowledge in the domain extensively. Once they were satisfied, they cut the list short to 30 suppliers.

The top management from MNO Nurseries met with these vendors and negotiated the pricing and other terms. After much deliberation, both parties came to a consensus on the terms and conditions.

After onboarding the suppliers, the team constantly monitored their performance.

Example #2

Dumarey Group, the European automotive giant, launched a procurement system for its suppliers and internal team in April 2024. The Dumarey group manufactures high-performance propulsion systems like engines and transmissions. Their operations are prevalent in 6 locations, employing over 3,000 people.

Their army of suppliers is over 2,500 across 40 countries. To manage such a large volume of suppliers, the Dumarey group wanted to streamline the process. Therefore, they teamed up with BearingPoint, who helped them automate and digitize the process. Through this, they were able to streamline the process and monitor supplier performances more efficiently.

Best Practices

It is crystal clear that no business can thrive without its suppliers. Therefore, it is essential to ensure that vendors succeed while also ensuring they fulfill their end of the bargain. The efficient way to ensure that happens is by prescribing a set of best practices to be followed. A few of the most common ones are mentioned below.

- The foremost step towards having an efficient procurement cycle begins with making sure the supply chain and the business goals are in the same line. Ensuring these factors not only ensures that procurement initiatives and organizational goals are fulfilled but also

- A supplier is more than just someone who supplies goods to ensure the organization's customers are satisfied. They are, in fact, partners in the organization'sorganization's growth. Therefore, it is vital to choose suppliers who resonate with the same ideology and goals.

- When an organization bestows its trust in a supplier, it must be backed with relevant documentation as well. As in, word-of-mouth agreements in this regard could be legally troublesome. Hence, drafting a service level agreement right from the outset is non-negotiable.

- If an organization has numerous suppliers, it is always better to use supplier management software as it makes it easier to manage and track all suppliers in one place.

- Every time a supplier is onboarded, the process must clearly educate the vendors as to what is expected of them and their products with respect to quality, timely delivery, price, and other terms and conditions.

- If years of business have taught business people anything, it is always to have a plan B, plan C, or even plan Z. Because even the top supplier can have a bad patch and not deliver as per the expectations. In situations like these, contingent suppliers shall save the day.

Benefits

Even though the benefits of the supplier management system have been mentioned in bits and pieces throughout the article, a more detailed version is mentioned in the points below.

- Efficient management of vendors ensures that the organization gets the best possible price. Therefore, they experience a significant reduction in costs, and they can pass on those benefits to their customers.

- Once a proper system is established, the communication between businesses and their suppliers is highly efficient. Improved communication helps vendors understand the intricacies of the businesses they serve. Thereby, there is greater efficiency in the process.

- The easiest way to drive away customers is regular or extreme price fluctuations. Establishing a process with suppliers gives them an advantage of fixed pricing, or sometimes they take benefit of scaled increments to ensure more extended contracts for their suppliers.

- By constantly communicating with vendors, there is a greater probability of finding areas of improvement in the process. These discussions lead to the overall growth of the process, which is way more than that of orthodox methods of procurement.

- An ideal buyer-seller relationship will lead to the supplier being entrusted with a particular part of the buyer's process. These activities could be inventory management or customer service at a few levels.

Supplier Management Vs Vendor Management

Supplier management relationships and vendor management are the same. However, there are significant differences in their fundamentals and intricate details. The distinctions are as mentioned below.

Supplier Management

- It focuses primarily on overseeing relations with suppliers who supply goods or services to the business/organization.

- The emphasis is placed on the selection, evaluation, and management of suppliers to make sure quality goods or services are delivered on time and at competitive pricing.

- The process involves selection, negotiation of terms, performance monitoring, and management of risk.

- Its principal focus is on maximizing value, eliminating risks, and encouraging collaboration between buyers and suppliers.

Vendor Management

- It is the process of overseeing relationships with suppliers and vendors who might provide not just goods or services but also technology solutions.

- Vendor management widens the scope as it also combines managing relationships external to the organization. IT vendors and service providers are classic examples.

- Its primary focus is on optimizing vendor relations to make sure they are in line with the organization's goals.

- The process includes functions such as vendor selection, negotiation, risk management, and performance monitoring for multiple functions of the organization's business.