Table of Contents

What Is Supply Chain Visibility?

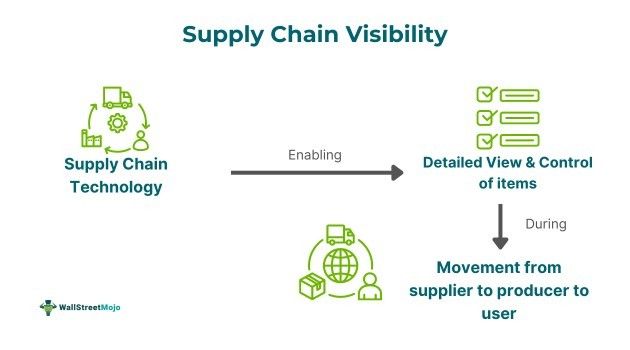

Supply chain visibility (SCV) refers to the capability of a firm to monitor single components, raw materials, sub-assemblies & finished goods as they move from vendor to producer to end-user. It helps makeover firms around stockouts, preventing bottlenecks, monitoring goods until delivery and adhering to directives.

SCV works with the help of technology in supply chain management, providing real-time information regarding logistics and miscellaneous aspects of the company's supply chain. It applies to visibility within a firm's operational field and throughout its partner network. It brings transparency to the supply- chain, enhancing efficiency and supplier-customer relations, leading to higher profits.

Key Takeaways

- Supply chain visibility (SCV) enables firms to track finished goods, raw materials, sub-assemblies, and components from supplier to producer to consumer, preventing stockouts, bottlenecks, and adhering to regulations.

- Its types include end-to-end, inbound/outbound logistics, supplier/vendor visibility, inventory visibility, and demand visibility.

- It can be enhanced by using advanced technologies like real-time tracking, IoT devices, and RFID, utilizing predictive modeling and data analytics, cloud-based visibility platforms, and workforce training.

- It faces challenges like potential disruptions from global events, geopolitics, and natural disasters. Lack of real-time data, communication issues, and fragmented views.

How Does Supply Chain Visibility Work?

Supply chain visibility (SCV) represents a technology offering an exhaustive view and stricter control of the transfer of finished goods from raw material procurement to production to delivery at the customer's doorstep. It has opened the doors for companies to handle control of their logistics operation transparently using SCV. Such a detailed view becomes possible only with the creation of a massive data set using technologies for operating supply chains. Moreover, it has been made possible by using advanced technologies such as AI, RFID sensors, GPS & IoT, providing deep insights into shipment, order and inventory status.

SCV works by:

- Integration of the above-mentioned technologies & supply chain visibility software to track assets and products in real-time across the supply chain.

- Then the data collected gets analyzed using predictive modeling and advanced analytics to create actionable insights.

- All these data help businesses adjust and make decisions in real time to increase operational efficacy, mitigate risks, and improve consumer loyalty and satisfaction.

SCV implementation & supply chain visibility solutions have various implications like decreased costs, on-time deliveries, brand reputation enhancement and customer service improvement. It has led to resilient and agile supply chains capable of transforming market changes. It reduces operational costs, leading to better financial performance like cost savings, increased revenue and significant returns.

Types

In the field of SCV, different types bring separate insights, as detailed below:

- End-to-End Visibility: It consists of the entire journey of the supply chain, starting from raw materials to customers. It offers panoramic viewing for analyzing and tracking each phase of manufacturing, logistics and delivery.

- Inbound & Outbound Logistics Visibility: It focuses on aspects of transportation, enabling optimizing routes, timely deliveries, and real-time monitoring of shipments, decreasing transportation costs and minimizing delays.

- Supplier and Vendor Visibility: It dives deep into the activities and performance of vendors and suppliers, leading to reliability, risk evaluation and encouraging collaborative partnerships.

- Inventory Visibility: It centers on tracking inventory levels and real-time locations, helping businesses optimize inventory levels, cut carrying costs, and thwart overstock and stockouts.

- Demand Visibility: It focuses on evaluating historical data, customer behavior and market trends to forecast demand accurately. As a result, proactive stock management is enabled to ensure product availability as and when and at any place needed.

Examples

Let us use a few examples to understand the topic.

Example #1

An online article published on 30 July 2024 discusses the acquisition of another company, aDolus Technology Inc., by Exiger to enhance its software concerning the visibility of the supply chain while the cyber threats increase. Meanwhile, one expects that these threats related to the visibility of the supply chain will triple in 2025 from 2025, affecting 45% of firms. In response to these threats, the American government has issued an executive order no. 14028, containing requirements- FDA SBOM along with CISA guidance.

Further, SBOM analysis and generation capabilities of aDolus can integrate into the Ion Channel platform of Exiger, resolving vulnerabilities in legacy and operational technologies. As a result, the capabilities of Exiger & aDolus give complete visibility of the cyber supply chain to vital sectors like healthcare, energy and telecom. Thus, the current acquisition complements the older ones and helps national security consumers and important asset owners.

Example #2

Let us assume that a major electronics manufacturer, Electra, has collaborated with Smartlogist, a provider of visibility of the supply chain. Smartlogist easily integrates blockchain technology and IoT sensors throughout the supply chain of Electra. The supply chain manager, Bella, observes real-time data obtained from Sydney factories to the Old York warehouse utilizing a centralized dashboard.

In case of any shipment delays because of rough weather in the Pacific Ocean, then Bella could easily reroute the shipment to safe and faster routes. Also, the lead times for raw material obtaining to finished products decreased by 25%, improving customer satisfaction. Furthermore, the data analysis predicts when demand surges, allowing Bella to optimize stock levels and bypass stockouts. Hence, such increased supply chain visibility enables efficient and seamless operations for Electra.

How To Improve?

To improve SCV needs, many elements to be weaved into one direction as follows:

- One must employ sophisticated technologies like real-time supply chain visibility tracking options, IoT devices and sensors to capture and relay data throughout the supply chain. It can also be used with RFID technique to enable firms' accurate asset tracking.

- One can also deploy predictive modelling techniques and excellent data analytics in transforming raw data into action-taking insights. So, it will facilitate optimized inventory levels, well-informed decision making and active resolution of potential challenges.

- Cloud-based supply chain visibility platforms could be used for seamless communication, collaboration, and collaborative programs to facilitate real-time data exchange, promoting transparency and fostering quick issue resolution and decision-making.

- One must ensure clarity and consistency, operations streamlining, and minimizing errors towards an optimized and enhanced supply chain through a benchmarking procedure of information sharing, data exchange and workflow management.

- One must invest in training and skilling of the workforce to enable staff to adapt and take advantage of evolving supply chain technologies. As a result, it maximizes the processes and technologies potential towards a highly effective supply chain.

Benefits

It brought numerous benefits to companies in the modern complex market place as listed below:

- It acts as a strategic lever releasing multiple outcomes instrumental for company operations.

- It has given a tool to companies for adjusting their production levels, maximizing stocks, and streamlining distribution channels to counter market trends and consumer preference fluctuations.

- It aids in understanding and identification of risks like interruptions of the supply chain, geopolitical issues and unforeseen catastrophes. Hence, companies can successfully execute contingency measures and risk-minimizing strategies.

- It improves customer satisfaction & loyalty by providing timely deliveries, stockout reduction, and real-time and accurate order tracking information.

- It reduces costs and propels toward operational excellence by identifying sectors for procedure enhancement, optimizing stock levels and improvement in transportation routes.

- It provides detailed insights facilitating data-led decision-making, empowering businesses to streamline their strategies with operational efficiencies, risk assessments and market demands.

Challenges

Currently, many challenges have hindered SCV like below, which need to be overcome for effective supply chain management:

- Separate departments have to operate in an isolated capacity, leading to fragmented views and lacking cohesion in the supply chain, creating hurdles in well-informed decision-making and detailed insights.

- Most supply chains lack instant & real-time data, resulting in deficiencies, delays and incapability to react quickly to disruptions.

- It is commonplace that stakeholders have hindered the exchange of information due to bad communication channels and collaborative techniques. Hence, they lead to missed optimization avenues, misinterpretation, and delays in SCV.

- Negative global events, geopolitical issues and natural disasters often disrupt continuous goods and information flow. Therefore, in such situations, one needs to have contingency planning and strategies of proactive risk management to sustain the supply chain and its resilience.