Table Of Contents

Difference Between Supply Chain and Value Chain

A supply chain is a network of entities that source raw materials, transform them into finished goods, and then distribute or sell them to customers. In contrast, a value chain refers to creating or adding value to the end product at every step, from conception through production to delivery and support.

Supply chains are more of an operational management strategy than value chains that are part of business management. A streamlined supply network focuses on minimizing costs, delivering on a customer's request, and ensuring customer satisfaction. Conversely, value addition emphasizes innovation, testing, and marketing of a product to provide businesses with a competitive edge and increase customer value.

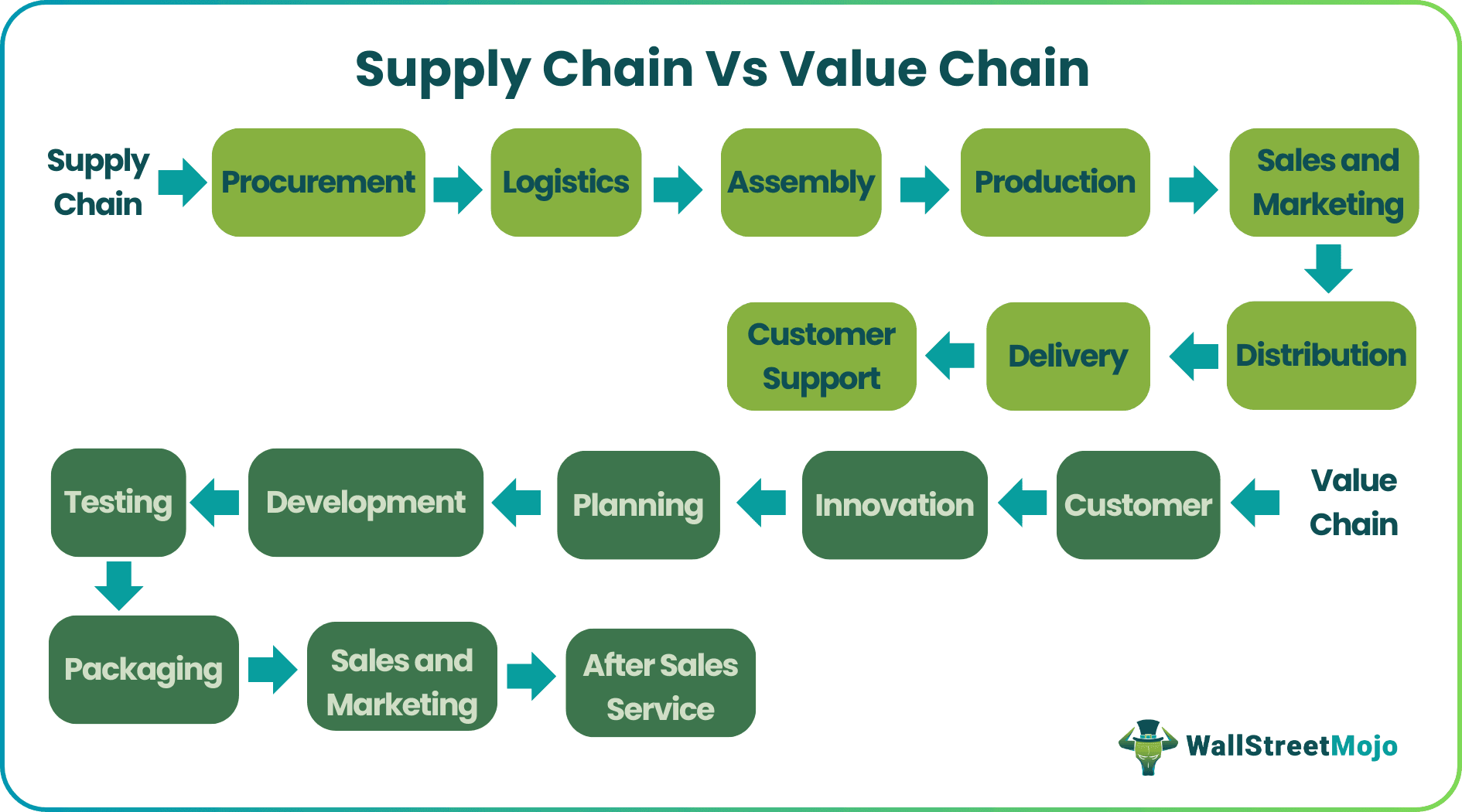

Supply Chain vs Value Chain

People often use supply chain vs value chain synonymously, though the two terms are entirely different in approach and essence. The confusion, however, is because both networks have a few participants in common, such as logistics and the delivery process.

One of the fundamental differences between the supply chain and value chain is that the former deals with the production and distribution of the product. The latter adds value to a product at each step of the process, including planning, designing, development, and delivery. The supply chain has nothing to do with adding value to the final product.

Secondly, the supply chain starts with the supply of raw materials and ends with the delivery of the finished product, often including services like expedited shipping to ensure faster delivery The value chain begins with searching for high-quality raw materials and ends with adding value to the product. Furthermore, the former involves a series of entities and activities that start from the supplier and ending with the customer. But the latter entirely focuses on activities, such as innovation, development, and marketing, thus adding value to a product before delivery.

Additionally, a supply network stems from operational management, with the supplier being the point of origin. Alternatively, the customer is the point of origin in a value network that constitutes business management. While the former aims to satisfy customers, the latter seeks to gain a competitive advantage. Unlike a value chain that considers the customer demand to develop the finished product, the supply chain begins with accepting the product request and concludes with the delivery of the final item to the end-user.

Supply Chain vs Value Chain Comparative Table

Let us have a quick look at the differences between supply chain vs value chain:

| Particulars | Supply Chain | Value Chain |

|---|---|---|

| Definition | Involves businesses, persons, and activities for the procurement, logistics, transformation, and delivery of finished goods | Involves activities to analyze customers, plan the production, and add value at each step of the process |

| Process | Operational management | Business management |

| Activities | Facilitates production and distribution of the product | Adds value to the product |

| Order | Start with the product request and ends with the product delivery | Begins with the customer request and concludes with the product development |

| Objective | Offers customer satisfaction | Provides a competitive advantage |

| Key Steps | Order processing, procurement, logistics, production, assembly, marketing, distribution, delivery, and customer support | Research, innovation, development, testing, packaging, sales and marketing, and after-sales services |

Infographics

What Is A Supply Chain?

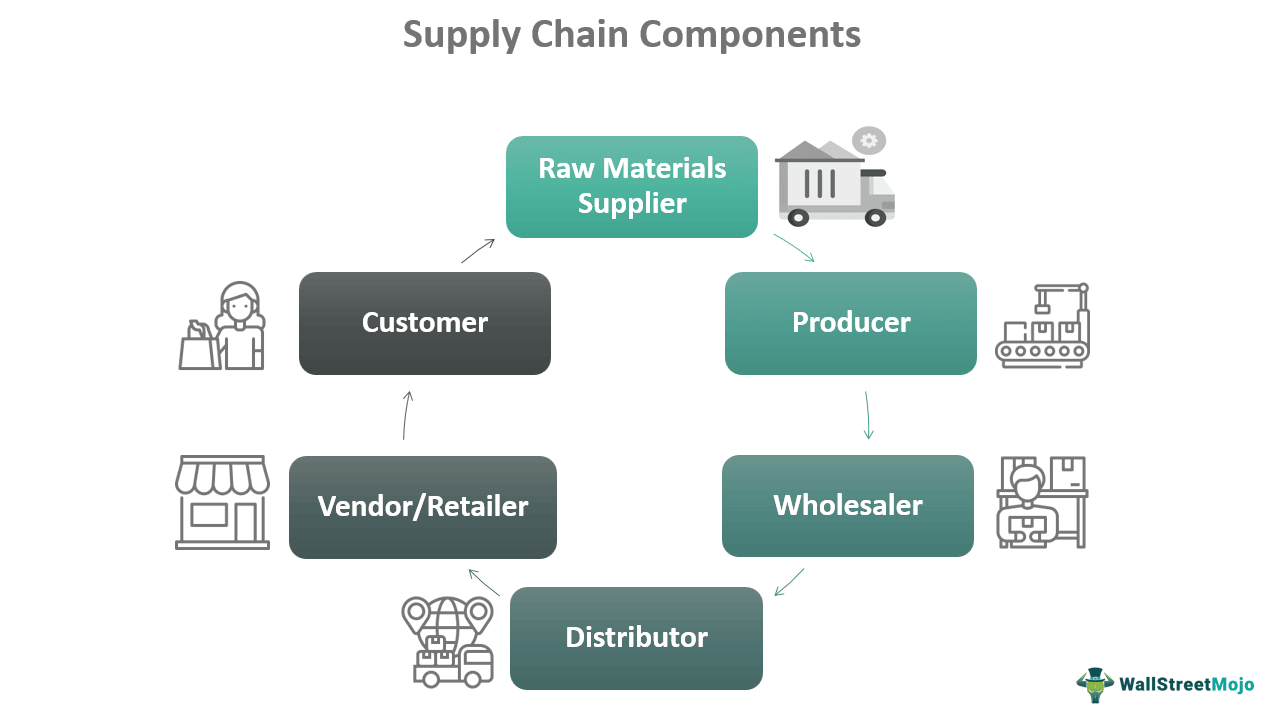

A supply chain is a network of participants that manufacture and distribute a product or service at the right time, place, and price. The channel partners include supplier, producer, wholesaler, distributor, vendor, retailer, and the customer. It involves the efficient flow of physical goods, the transmission of information, and cash transfer from its point of origin to its final destination, i.e., from the producer to the customer and vice versa.

In a supply chain, the supplier supplies raw materials to the manufacturer for transformation into finished goods. The distributor then distributes these items to the retailer that finally sells them to the customer. All these supply points can track the product at every stage of delivery. It also establishes a queue of participants to retrieve the item, for which the client demands a return or exchange if they are dissatisfied with it.

An efficient supply chain improves product quality, lowers costs, and ensures that firms never run out of inventory. Key steps involved in the process include order processing, procurement, planning, logistics, production, assembly, marketing, distribution, delivery, and customer support. The network participants coordinate on manufacturing and transportation while keeping the consumer cost low and business profit high. Hence, this process of systematic planning and regulation is considered supply chain management.

A supply network uses existing information, resources, and finance to manufacture a product and then sell it to the end-user. Also, the process is critical in ensuring the seamless operation of any firm that relies on raw materials. It, in turn, generates revenue for the company in exchange for the sale of finished items. Sectors benefiting from this arrangement include logistics, manufacturing, e-commerce, energy, etc.

Example

When a user orders a product online, the e-retailer forwards the order to the respective brand. The supplier then dispatches the item, and the logistics company ensures that it reaches the customer on time. In case of any discrepancy with the delivered product, the user can request a return, refund, or exchange, which will again follow the same path but in reverse order.

What Is A Value Chain?

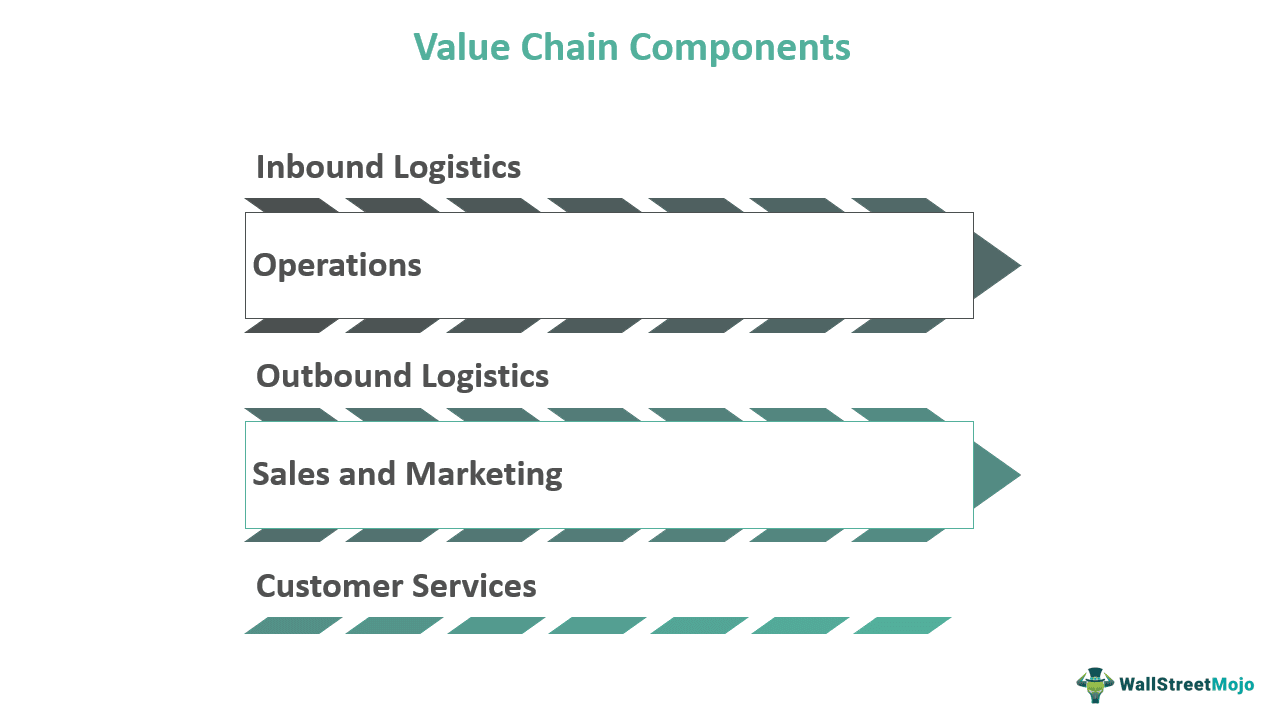

A value chain is a series of activities in which entities collaborate at each step to deliver a product that fits the consumer's needs in every way. When an item progresses through these stages, it gains more value. Activities that make the value chain network effective include inbound logistics, operations, outbound logistics, sales and marketing, customer services, etc. Product planning, cooperation, and inventory shortage reduction are some best practices managers use throughout the process.

Value addition to a product relies heavily on a company's core strengths, including designing, manufacturing, differentiation, and distribution. In other words, paying attention to procurement, production, quality control, and distribution can add value to products or services. Furthermore, understanding consumer demand, human capital management, and technological advancements are critical for producing accordingly.

There are products in the market that appear to be in the same category and function similarly, yet their prices are vastly different. It is because more expensive brands provide more value in their products. Adding value, however, does not always imply improved features and functions but rather a variety of other factors, such as after-sales services.

An efficient value chain can result in targeted efforts, cost savings, and waste reduction. It may, however, increase the cost of products or services delivered to consumers. Analyzing customers, planning the production, adding value at each step of the process, and assessing its significance in providing a competitive advantage to the company are crucial parts of the Value Chain Analysis. The concept proposed by American academic Michael Porter assures the ability of a product or service to offer value for money.

Example

Let us say Barbara buys an electronic item from a particular manufacturer, but she does not get a response from customer care or after-sales service when she needs it. Barbara will never choose the brand for any other goods in the future if this happens. Also, she will only have negative things to say about the company. It will irreparably damage the brand's reputation. On the other hand, a high-quality electrical product with reliable after-sales service will add value to both the product and the brand.