How To Model Equipment Replacement In Foodservice?

Table of Contents

Introduction

In the foodservice space, the smooth functioning of companies’ day-to-day operations depends on their equipment. Be it dishwashers, ovens and refrigerators or ice machines from Ice Machines Plus, all appliances play a key role in ensuring safety, efficiency, high-quality service, and customer satisfaction.

Considering that any piece of equipment requires replacement as it comes to the end of its life cycle, engaging in equipment replacement modeling is necessary. By building a model and having a clear plan, companies can avoid machine breakdowns and subsequent operational disruptions. Moreover, through effective replacement planning, organizations can save capital by not choosing to swap machines too early.

So, let us find out how companies create such a model and ensure efficient equipment lifecycle management.

Start With Useful Life

The equipment replacement modeling process starts with the projection of the appliance’s useful life. While equipment manufacturers may offer an estimate with regard to the life cycle of their product, it is important not to strictly follow that. After all, various factors typically impact the useful life of machinery. Some of these elements include surrounding conditions, maintenance, usage, etc. Hence, it is vital to factor in these aspects to get an estimate.

Add Failure Probability

Incorporating the probability of failure into the process is crucial. This is because it aids in maintenance schedule optimization and reduces the overall cost of operating the equipment. Note that individuals may consider using probability distributions, for example, the Weibull distribution, to determine when the risk of failure surpasses a certain threshold. Modeling failure times is key to having a proactive approach and formulating an effective asset replacement strategy.

Depreciation And Value

Calculating the depreciation of a piece of equipment is a vital step in the equipment replacement modeling process. The computation helps track the decline in the value of an asset over time. This, in turn, allows for informed capex decision-making as it enables companies to determine the ideal time to replace the equipment. Note that there are various ways to calculate depreciation. Out of them, two popular techniques are the straight line method and the reducing balance method.

Salvage Value And Disposal

In foodservice equipment planning, it is vital for companies to determine the salvage value at the end of a machine’s useful life. This is because it denotes an inflow of cash and can cover a portion of the cost of replacing the asset upon its disposal.

Downtime Costs

Another crucial factor to take into account when carrying out the equipment replacement modeling process is the downtime costs, which are a key aspect of cost analysis in foodservice. These costs refer to the losses incurred by a business owing to its inoperability or unavailability. Think of it as the cost incurred per hour owing to the inability to provide service. For example, suppose a business makes $100 per hour by using its sandwich maker. This amount is the money the business loses every hour if the asset is non-operable. In other words, it is the downtime cost.

To integrate this element into the equipment replacement model, one must factor in the probability of incurring downtime costs. This will make sure that they have a proactive approach and replace the machine before it begins malfunctioning.

Scenario Analysis: Seasonality And Lead Times

Procuring new equipment for a foodservice business is not always straightforward. Indeed, when the machinery is not easily available or has to be imported, it becomes even more difficult for companies. The period for which they need to wait to get the new equipment is the lead time. If the lead time is high and the existing machine starts malfunctioning, carrying out operations can become a serious issue. In fact, the company might be forced to halt operations altogether.

That’s why scenario analysis is essential when carrying out equipment replacement modeling. It allows companies to be one step ahead and ensure that the new machine is ready to replace the existing one as soon as it starts malfunctioning. This ensures there’s no impact on operations. It is important to consider seasonality as well. After all, replacing machines during peak seasons can be quite challenging owing to the high demand.

Capacity-Driven Wear

As noted above, there are various factors influencing a machine’s useful life. One of them is usage. Even if two businesses have the same dishwashers, their life cycle may differ because of the usage. Hence, when building an equipment replacement model, it is vital to track and record key metrics, for example, hours of usage and cycle count.

Building The Model

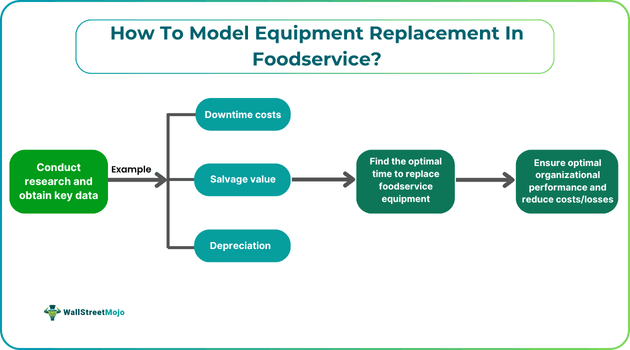

Once you accumulate all key data, for example, downtime costs, salvage value, depreciation, etc., make sure to use software applications like Excel to build the model. One can enter all the relevant information into a spreadsheet and observe how the costs associated with an asset change periodically, for example, over 1 year, 2 years, or 3 years. This will help them determine the optimal time to replace the equipment. Note that individuals can also utilize simulations to assess different scenarios and make informed decisions.

Research Step

When engaging in equipment replacement modeling, it is vital to remember that how you perform your research will play a vital role in your success. Make sure to discuss with key staff members to gather accurate data related to usage, downtime, etc. Also, make sure to talk to suppliers to have a clear idea regarding product availability, lead time, etc. All these insights will help you build a model based on which you can make key decisions concerning your foodservice business.

Keep It Simple And Current

When engaging in equipment replacement modeling, it is vital to understand the importance of keeping everything simple and avoiding complexity. The more one complicates things, the more difficult it will be to get the insights required for making key decisions. Experts recommend focusing on gathering key data related to assets through extensive research, updating the model with relevant information whenever necessary to maximize the chances of success.

The Payoff

The result of carrying out effective equipment replacement modeling is simple. Through this process, businesses can adopt a proactive approach and replace their appliances and tools at the right time. The data-based decision-making, in turn, will allow them to minimize costs and optimize organizational performance.