Table of Contents

What Is Enterprise Asset Management (EAM)?

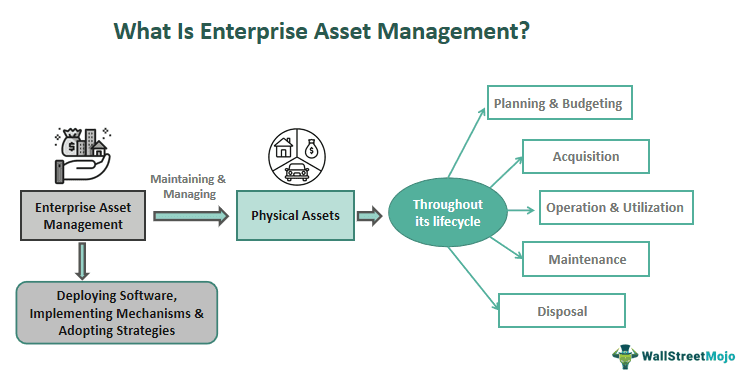

Enterprise Asset Management, or EAM, is a collaborative process where software, systems, and strategies are incorporated to ensure proper maintenance of physical assets throughout their lifecycle. It ensures improving its usage and looks after the quality and environment in parallel, reducing operational costs.

Such processes are typically used in enterprises that are majorly dependent on heavy machinery, plants, and equipment and are managed either by paperwork or company-based software. Still, in modern times, there are many enterprise asset management software programs specifically designed with the core creativity of EAM.

Key Takeaways

- Enterprise asset management is an amalgamation of systems, software, and strategies to maximize and safeguard the lifecycle of any organization's physical assets.

- Standalone software is built to enhance the EAM system and regulate the whole process smoothly.

- One of the most essential benefits of EAM for enterprises is that it minimizes operational costs in manufacturing and inventory management.

- EAM is different from CMMS, given that the latter focuses on the maintenance of assets to drive its uptime and not on the overall enterprise performance.

Enterprise Asset Management Explained

Enterprise asset management is the process of identifying the true value of a physical asset and optimizing it according to the needs and requirements to maximize the asset's production, efficiency, and life. Companies, in one way or another, own some physical assets, be it plants, heavy vehicles, tools, apparatus, machinery, and types of equipment. Hence, the entire enterprise asset management system aims to maintain these assets, including installation, procurement, compliance, risk management, decommission, and disposal.

Some important industries and business examples that cater to EAM are oil and gas, utilities, industrial machinery, railways, construction, etc. The enterprise asset management definition elaborates on how the company takes advantage of the optimal use of EAM and becomes efficient with its production and efficiency.

Many enterprise asset management companies specialize in creating system modules and focus software on helping firms not only cut costs but also provide better customer service. Without EAM, many companies would suffer considerable losses in their operations, given that they would be unable to take full advantage of their assets. Even employees working in an organization like to use EAM software solutions to ensure easy and flexible task completion and automated, timely maintenance of assets, which saves a lot of time.

Examples

Let us consider the following instances to understand the concept better:

Example #1

A good EAM example comes from the railways; in the last few years, Europe's transport sector has become highly unpredictable. The pandemic is a primary reason for this. Still, after the pandemic, the rising inflation, remote working style, and changing market structure brought overall economic instability in the European countries. Amidst this, European countries have come up with net zero goals, and the railways have become the backbone of European transport. Hexagon, an asset lifecycle intelligence company, has created enterprise asset management tools and believes that the proper use of technology can solve the problem of unpredictability and increase the asset's efficiency.

The company's main goal is to focus on sensor data and use AI methods to forecast specific equipment usage. The more rail companies use and become familiar with the sensors, the better it is, as more data will be produced and analyzed to get insights and create actionable strategies.

Example #2

Per the January 2023 report, Australian-based Hardcat partnered with an Indian data center, Mumbai-based Yotta, to launch an enterprise asset management platform. The partnership aimed to ensure proper management of assets, with the Mumbai firm working with the government and private sector and the Melbourne counterpart exercising complete control and help in firm decision-making. Hardcat shares a vast clientele with 2000+ odd customers, including big names like Toyota, Siemens, Airbus, Honda, Ford, Sydney Opera House, etc. This partnership explored new horizons for India's growth and development in client servicing and technology.

Benefits

Enterprise Asset Management offers numerous benefits by allowing firms to think beyond horizons and come up with ideas to leverage an asset's lifecycle. Some of the advantages of EAM include the following:

- The system enables maximized return on assets by improving its life cycle, efficiency, and quality results.

- It helps break down large and complex tasks into manageable and small work.

- The more a company works on its physical assets, the better customer service they provide.

- Using EAM software helps a company reduce operational costs.

- The system eliminates paperwork, reduces human error, and offers a digitally enhanced structure.

- Timely maintenance of critical assets is regulated and easily managed with the help of EAM.

- Enterprises can resolve issues before they appear with the help of EAM.

Enterprise Asset Management vs CMMS

When it comes to asset management, there are two perspectives that add to the maintenance and management of physical assets. One is the EAM, and the other is the Computerized Maintenance Management System (CMMS). Though they form parts of physical asset management, they differ widely from each other. Let us have a look at some of the distinctions below:

- While enterprise asset management is used to preserve and maximize the lifecycle of assets, CMMS, as the name suggests, is an automated system that processes maintenance tasks as per schedule and tracks them.

- The former deals with overall performance enhancement of the physical assets, whereas the latter is all about driving asset uptime.

- EAM involves tracking the entire lifecycle of an asset, starting from planning to procurement to maintenance to renewal or disposal. On the contrary, CMMS starts tracking an asset once purchased and operational.

- The former follows a phased implementation cycle as it covers a comprehensive approach toward asset management across an enterprise. The latter, on the contrary, has a single implementation cycle to follow