Table Of Contents

What Is The Full Form Of MFG - Manufacturing

The full form of MFG is Manufacturing. It converts raw material or assembling parts into finished goods or finished goods with the help of hand, labor, machines, tools, chemicals, etc., in such a manner that the goods produced have entirely different characteristics, appearance, and use from its raw materials.

There are different forms of manufacturing, like discrete, batches, etc. Examples of manufacturing include automobile manufacturing, Electronics manufacturing, etc. The manufacturing process has radically transformed over a period under which technology intervention is increasing and human intervention is reducing, thereby leading to unemployment problems for economies.

Full Form Of MFG Explained

Manufacturing is the process of converting, assembling, and changing raw material into a product that is entirely different in use and the appearance of it from raw material. The process of manufacturing started during ancient times. It involves usage of various tools, machines, human capital and different types of chemicals.

By manufacturing goods and converting them into something that is more useful than the raw materials, the process is able to meet the requirements of consumers in the market by supplying products which have a huge demand. Due to this there is a price that consumers pay to the manufacturers for such goods, and the latter earns profit. The higher the price of the finished products, the higher is the revenue and profit, provided the cost of manufacturing is kept under control.

Mass production or large-scale manufacturing helps in meeting heavy demands and the overall cost also comes down. However, updated and advanced technologies and good quality machinery is required for the same. The workers should be trained and skilled enough to understand how to handle the process. This not only requires large capital investment but also continuous innovation and generation of new ideas to make things better.

The more efficient the process is, the less is cost incurred. The resources are used properly with minimum wastage. Companies are able to remain competitive in that market. Manufacturing plays a very crucial role in an economy. A high level of the same indicates that the economy has demand for various products and services and it is able to invest in mass production by setting up manufacturing units, which also creates employment, boosts international trade and leads to overall infrastructural development.

History

For ages, people have found different ways to convert raw materials such as oil, wood, food, and other stuff into finished goods like gas, furniture, eatables, etc. It started the industrial process, which converted raw materials into finished products in large quantities and turned into the industrial revolution in the 19th century. Earlier, these products were made by hand. These processes, in turn, helped to increase production with reduced labor work.

Huge production and assembly line manufacturing helped companies make parts that could be used individually and helped production more rapidly by lowering the customization process. The age of computers and high-tech gadgets has helped companies achieve a more reliable and accurate manufacturing method. However, outputs of such companies require skilled labor and more capital investment.

The method of operations and processes used have changed with time in the manufacturing process. Many jobs in the manufacturing sector with low skills have been transferred from developed to developing countries because labor in developing countries is cheaper. High-tech and skilled manufacturing is carried out in developed economies. As a result, labor is more productive, and manufacturing is more efficient. As a result, production increases in massive quantities, but the number of human interference has decreased drastically.

Types

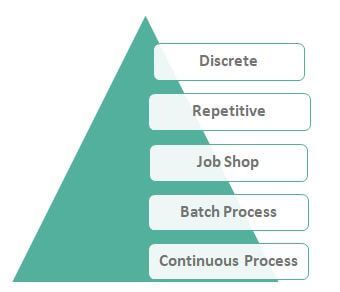

The following are the types of manufacturing –

#1 - Discrete

The discrete method provides a variety of produced products. It is a dynamic methodology and can vary from a few steps to frequent steps of change. The result of products may be the same or can be different from each other.

#2 - Repetitive

The most common and long-established method is repetitive manufacturing. Under this method, the same product or of similar nature or the same family frequently produces one after another. But this method doesn’t provide huge opportunities to fulfill expectations.

#3 - Job Shop

The job shop doesn’t have a production line and provides one product at a time. Most of the time, these are done on customer demand and don’t relate to finished products. These are always more expensive as one product is being made at a time and doesn’t give better opportunities.

#4 - Batch Process

In the manufacturing industry, goods made in batches combine to make a single batch. The batch process may cover many small batches over time or one batch with a huge quantity over its span. Therefore, one can carry it out over a long period.

#5 - Continuous Process

A continuous process is quite similar to a repetitive process as both run all the time. The main difference is the raw material used may be liquids, slurries, powder, or gases.

Process of Manufacturing

The manufacturing process will depend on the type of finished goods produced and is unique for each material produced. However, in common, every manufacturing process will involve conversion, assembling, or working upon raw material with the help of either man, machine, or other equipment. After the conversion, assembling, or working, the manufactured product will have an entirely different appearance, characteristics, uses, etc.

. However, let us study the process or steps in detail.

- Idea generation – Before the production starts, it is necessary to create a plan or a concept about how the arrangement will be organized. Thus, there should be an idea that will be nurtured depending on the type or nature of good, type of consumer, the demand and level of competition. All the above will help in structuring the product.

- Market research - This is very important as it will give an clear idea about the type of demand, its level, the prevailing price, competitions, etc. It also gives an idea about how to improve the product quality to increase sales, or what is the price level that will fetch maximum customers and at the same time cover the manufacturing expenses.

- Design – With proper research and study, a proper design is created that will successfully meet the consumer need and requirement. It is necessary to keep in mind the cost of designing which will affect the profitability of the business. It is also necessary to note the limitations of similar products existing in the market and design the current one to increase customer base.

- Finalize and testing – This is crucial because this will ultimately lead to the start of production process. The final decision includes procuemnt of raw materials, and other resources capital investment and implementing all to produce a prototype to check whether the idea works. The testing will bring out any errors, defects and limitations that should be dealt with at the earliest. If testing process is not full proof, it will have negative implications on the actual production process.

- Manufacturing – Finally the manufacturing process starts where all resources like plant, labor, machinery, capital etc is put together to set up the process in full scale. There also has to be inventory storage facility depending of the type of good and arrangememt fro transportation of the same from the plant to the point of sale. The supply chain should be efficient and dependable.

- Monitoring – Every manufacturer should monitor the entire process to ensure that it meets the criteria and does not deviate from the planned procedure. Continuous evaluation and assessment of cost, revenue, profits and resource utilization is important so that things proceed as per the expectations. Depending on consumer taste and preferences, the supply, design, usefulness etc should be regulated to get the best result.

Thus, the above are some basic steps which are used to convert raw materials to finished goods that to meet market demand.

Examples

Let us understand the concept with the help of some suitable examples.

- Transportation MFG – These include automobile manufacturing transportation equipment.

- Electronics like mobiles, TVs.

- Fast-moving consumer goods – Cosmetics, food, beverages, soaps, detergents.

- Chemical Industry – Supply of chemicals used in various industries.

- Paper industry – Manufacturing of pulp and related products.

- Pharmaceuticals industry – Making of medicines, medical devices, and healthcare.

- Printing and publishing – Books, colors, etc.

- Industrial equipment – Infrastructure needs and heavy equipment.

- Furniture and fixture – Sofa, bed, cushion. Almira.

Advantages

Some advantages of the concept are as given below.

- Increase in Efficiency - Quality is the foremost requirement in manufacturing and can be achieved only by using machines, technology, and labor as a part of the manufacturing process. It has made manufacturing more efficient by reducing errors, defects, and other factors.

- Lowering the Cost – Cost is the basic factor that affects the business. The lower the cost, the more profit. If the process is efficient, there are fewer mishaps, less waste, and saves more money.

- Rapid Production - The manufacturing process includes machines, less labor, and works more efficiently and faster.

- Research – The process of research helps in not only understanding the market, the type of demand and kind of customers for the same, but also engage in discovering new methods of production, upgraded machinery and techniques that will make the entire process efficient and cost saving.

- Integration with supply chain – This will ensure that the raw materials are procured on time without any blockage, like labor issues, price negotiation related problems or lack of material availability. It will also ensure that the products reach the markets on time to meet consumer requirements.

Disadvantages

Some disadvantages of the concept are as follows:

- Task-Oriented - The manufacturing process involves machines and technology, which are automatic, so they will do whatever is programmed. Therefore, creativity reduces as there is no human intervention.

- Increases Global Issues - The manufacturing process is entirely technology-driven and machine-based. It requires gases, chemicals, fuels, and energy to run, producing industrial waste and dangerous gases contributing to global warming and substantially degrading our environment.

- Lowering Jobs - As machines are doing human jobs with more accuracy, human requirement reduces numbers and increases unemployment problems.

- Labor problems – If the production process is extremely labor intensive, it will involve a lot of workers who may misuse their demand and ask for more wages of work facilities, thus creating problem in the process.

- Supply chain problem – This may include inefficient supply chain who do not have enough experience. May other external problems like political and social instability, natural disasters, or any other economic crisis can affect the functioning of the supply chain.

- Regulation – It is necessary to comply with the rules and laws related to manufactuing. If this is not done, it leads to legal issues resulting in penalty and unnecessary problems that affect or stop manufacturing process, leading to losses.

Thus, these are some of the advantages and disadvantages of the concept which should be noted in order to design an effective strategy that will be sustainable and increase profitability.

Manufacturing Vs Production

Even though both the concepts are very similar to each other there are some points of differences between them, as given below.

- Manufacturing includes technology, machinery, software, and labor to make consumer goods that are saleable in the market, while production doesn’t deal with machines, the raw material to make its output.

- Manufacturing products is not an easy task in today’s dynamic business scenario as the inputs have to go through several processes to become output. Manufacturing requires the proper balance between machinery, workers, and input materials to get the final product. Production is only the additional process to make the goods saleable to consumers.

Thus, the above are some basic difference between both the economic terms.